Wednesday, 05 October 2022

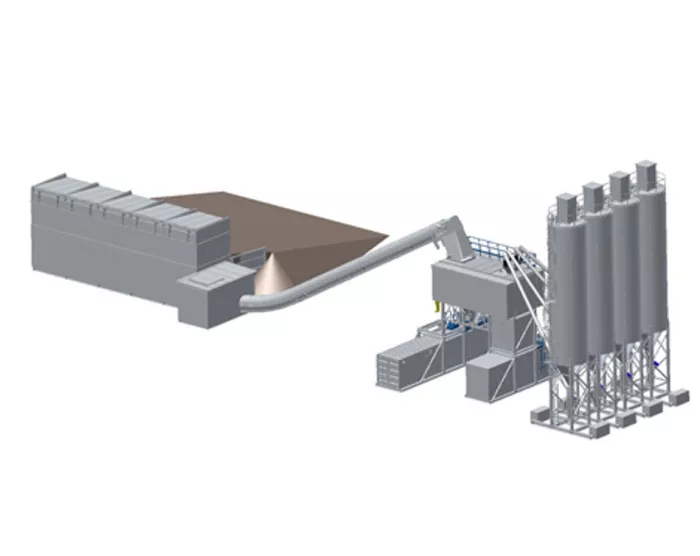

Kamet Express concrete mixing plant

When the privately owned ready-mixed concrete manufacturer MV Betoni wanted to expand its operations in the Tampere region in Finland, they immediately knew who to call.

Just over half a year after the first contact with Steel-Kamet, MV Betoni had a new plant ready for use in Kangasala.

— Often sales processes may take from a year to a couple, but with MV Betoni, the process was very fast, because we already knew each other as companies, says Mikko Rautio, Steel-Kamet’s Nordic sales manager.

The Kamet Express 100 concrete mixing plant with turnkey delivery was the selected plant model for MV Betoni. Steel-Kamet handled the delivery from the overall design to commissioning. Consequently, only earthworks and electricity and water imports on the site were left to the customer.

— One of the advantages of our Express model is pre-installed foundations. Thus, the customer does not have to do almost any preparations on the site before the plant arrives, and their valuable labour is not needed for installation and commissioning. Employees of the customer can therefore concentrate on their actual work. The assembly of the Kamet Express 100 is quick and, if necessary, it can be moved to another address within 24 hours, Rautio lists the best aspects of the model.

When the customer has clear wishes, a suitable solution can also be found faster. However, sometimes deeper planning and tailored solutions are needed. Variation of the modular Kamet collection provides a solution to most needs.

— Minor changes are almost always made. Although we supplied a standard design to MV Betoni, the colour of the plant was changed to suit the customer’s brand. From our side, the delivery went well and within the timeframe desired by the customer. This is a matter of honour for us, Rautio sums up.

The new plant with an excellent location increases the competitiveness of MV Betoni. From its plants located on both sides of the growing Tampere region, the company can better serve its customers. A new Lamminrahka residential area is also under construction near MV Betoni’s new plant in Kangasala. The area will contain homes for up to 8,000 residents and 1,000 working places in the future.

— Previously, we delivered concrete to Kangasala from our Nokia plant. Now, thanks to the location of our new plant, both transport costs and kilometres travelled in proportion to the amount of supplied concrete (in cubic metres) will be reduced. With current fuel prices, the saving is significant. We have also invested in new transport equipment, and all these elements together will significantly reduce also environmental consumption, says Ilkka Ylinen MV Betoni’s Chairman of the Board.

— Cooperation with Steel-Kamet worked out the same way as always with them — that is, excellently. Delivery was on time, and everything went as planned, Ylinen sums up.

Product: Kamet® Express 100

Plant capacity: 100 m3/h

Kamet® services: design, delivery, commissioning